I’ve spent about 2 days on dealing with the ADC (Analog to Digital Converter) of the Arduino platform. Turns out there’s more problems to overcome when dealing with taking analog signal from a sensor and converting it to meaningful digital reading.

The issue is that even with a constant input voltage the ADC reading sampling error rate is larger than I’d like (~1.2%) with some random spikes in excess of 3%.

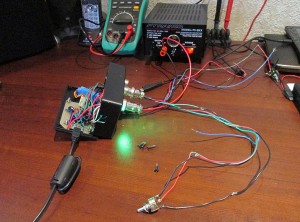

I built a test rig to troubleshoot the issue. Using constant input voltage and a potentiometer to simulate the analog input from a sensor.

Goal:

– At least 4 sample updates per second. (Smooth gauge updates)

– Stable voltage regardless of outside interference.

Things I found:

– Arduino Atmel chip uses a single ADC and multiplexes the input pins.

– Switching read pin on the ADC causes noise in the system. Solution to read the first value and totally discard it. Then wait at least 10ms before sampling actual data.

– Sample accuracy is inversely proportional to the delay between samples. Shorter delay between reads, less drift. But over a static period of time, the error rate is the same.

– ADC is quite sensitive to electronic noise. Adjacent pins seem to affect reading.

Things I tried:

– Average voltage over multiple samples (currently 11 samples per read)

– Add delay between readings (1 to 12 ms) (currently 2ms)

– Discard top and bottom values and average the rest (currently discard 25%)

– Add a delta value, discard new value if difference is less than delta (currently 0.011V)

– vary delay on multiplex debounce (currently 10ms)

Current sampling rate: 3.7 samples / second.

Final Arduino Code:

const int LED_RED = 9;

const int LED_GREEN = 8;

const int LED_BLUE = 7;

const int LED_ACT = 11;

const int INPUT_REF = 22;

const int INPUT_RATE = 20;

int refPins[4] = {19, 17, 18, 16};

int sensePins[4] = {15, 13, 14, 12};

double lastRefVolts[4] = { 0, 0, 0, 0 };

double lastSenseVolts[4] = { 0, 0, 0, 0 };

const float LOW_VOLTAGE = 4.5; //alert voltage for 5V bus

const int MAX_SAMPLES = 50; //max sample on trim pot

const float DISCARD_PCT = 0.25; //percent of samples to discard (top and bottom)

const float MAX_DELTA = 0.011; //ignore changes less than this

const int SAMPLE_DELAY = 2; //delay MS between sample reads

const int INITIAL_DELAY = 10; //delay MS on pin change

void setup()

{

//set pin IO modes

pinMode(LED_RED, OUTPUT);

pinMode(LED_GREEN, OUTPUT);

pinMode(LED_BLUE, OUTPUT);

pinMode(LED_ACT, OUTPUT);

for (int pin = 0; pin < 4; pin++)

{

pinMode(refPins[pin], INPUT);

pinMode(sensePins[pin], INPUT);

}

pinMode(INPUT_REF, INPUT);

pinMode(INPUT_RATE, INPUT);

//cycle leds

digitalWrite(LED_RED, HIGH);

digitalWrite(LED_BLUE, HIGH);

digitalWrite(LED_GREEN, HIGH);

setLED(LOW, HIGH, HIGH);

delay(200);

setLED(HIGH, LOW, HIGH);

delay(200);

setLED(HIGH, HIGH, LOW);

delay(200);

setLED(LOW, LOW, LOW);

delay(200);

setLED(HIGH, HIGH, HIGH);

//emulated serial, speed ignored

Serial.begin(38400);

}

void loop()

{

//read serial to clear buffer

if (Serial.available() > 0)

{

Serial.flush();

}

//get number of samples to read

int readCount = getReadCount();

//write +5V bus voltage

writeRefVoltage(readCount);

//write all input sensors

for (int pin = 0; pin < 4; pin++) {

writeSerialVoltage(pin, readCount);

}

}

void writeSerialVoltage(int pin, int readCount)

{

digitalWrite(LED_BLUE, HIGH); //blue off - start sending

digitalWrite(LED_ACT, LOW); //internal off

//ref volt, seems more volatile

float refVolt = getVoltage(refPins[pin], readCount);

float newRefVolt = processRefVoltage(pin, refVolt);

//get sensor voltage

float senseVolt = getVoltage(sensePins[pin], readCount);

float newSenseVolt = processSenseVoltage(pin, senseVolt);

Serial.print("IN"); //write identifier

Serial.print(pin);

Serial.print("\t");

Serial.print(newRefVolt, 4);

Serial.print("\t");

Serial.print(newSenseVolt, 4);

Serial.print("\r");

Serial.println("");

digitalWrite(LED_ACT, HIGH); //internal on

digitalWrite(LED_BLUE, LOW); //blue on - sending done

}

//do a delta comparison on Ref voltage

float processRefVoltage(int Pin, float refVolt)

{

float lastRefVolt = lastRefVolts[Pin];

if (abs(refVolt - lastRefVolt) < MAX_DELTA)

refVolt = lastRefVolts[Pin];

else

lastRefVolts[Pin] = refVolt;

return refVolt;

}

//do delta comparison on sensor voltage

float processSenseVoltage(int Pin, float senseVolt)

{

float lastSenseVolt = lastSenseVolts[Pin];

if (abs(senseVolt - lastSenseVolt) < MAX_DELTA)

senseVolt = lastSenseVolts[Pin];

else

lastSenseVolts[Pin] = senseVolt;

return senseVolt;

}

//send bus voltage to host

void writeRefVoltage(int readCount) {

float refVoltage = getVoltage(INPUT_REF, readCount);

if (refVoltage < LOW_VOLTAGE)

{

digitalWrite(LED_RED, LOW);

digitalWrite(LED_GREEN, HIGH);

}

else

{

digitalWrite(LED_RED, HIGH);

digitalWrite(LED_GREEN, LOW);

}

Serial.print("REF\t");

Serial.print(refVoltage, 4);

Serial.println("");

}

//read value from ADC (0-1023) and convert to voltage (0-5)

float getVoltage(int PIN, int samples) {

//allow ADC to stablize

analogRead(PIN); //ignore value

delay(INITIAL_DELAY); //wait for debounce

float sampleList[samples];

//read samples

for (int i = 0; i < samples; i++)

{

float voltage = (float)analogRead(PIN) * (5.0 / 1024.0);

//round to 2 decimals

sampleList[i] = (ceil(voltage * 100.0)) / 100.0;

delay(SAMPLE_DELAY);

}

//sort array (shitty bubble sort, cause i'm lazy)

float swapper;

for (int o = samples-1; o > 0; o--) {

for (int i = 1; i <= o; i++) {

if (sampleList[i-1] > sampleList[i]) {

swapper = sampleList[i-1];

sampleList [i-1] = sampleList[i];

sampleList[i] = swapper;

}

}

}

//discard % of top and bottom values, average the rest

int avgStart = max(samples * DISCARD_PCT, 1); //array start

int avgEnd = min(samples * (1.0 - DISCARD_PCT), samples); //array end

int avgSamples = 0;

float ret = 0;

//average out the values

for (int cntr = avgStart; cntr < avgEnd; cntr++)

{

avgSamples++;

ret += sampleList[cntr];

}

return ret / (float)avgSamples;

}

//read trim pot, get average samples

int getReadCount() {

analogRead(INPUT_RATE);

int readCount = analogRead(INPUT_RATE);

return map(readCount, 0, 1023, 4, MAX_SAMPLES);

}

//set RGB led values

void setLED(int RED, int GREEN, int BLUE) {

digitalWrite(LED_RED, RED);

digitalWrite(LED_GREEN, GREEN);

digitalWrite(LED_BLUE, BLUE);

}

Binary sketch size: 7,196 bytes (of a 32,256 byte maximum)

Estimated memory use: 103 bytes (of a 2,560 byte maximum)

This is probably as close as I can get to get an accurate reading that doesn't jump around too much. Filters most noise while giving a decent sample rate. Currently reading all 4 inputs. Technically could reduce to 3 inputs since 4th won't be used for a while. Will see how well Gauge Pod software deals with current feed rate.